Ultra Hard Technology

Fine ceramic valves have won numerous awards.

In the late 1960s, there was a big focus on the problems of pollution in Japan. In 1967 the "basic anti-pollution law" and in 1968 the "anti-air pollution law" were passed; in response, initiatives were launched by both the government and private sectors.

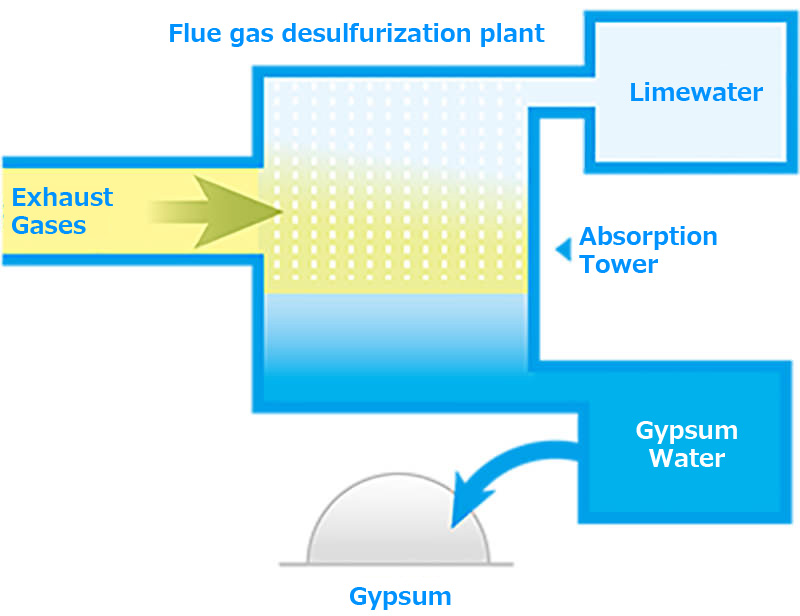

Under these circumstances, Fujikin focused on developing a valve for use in the desulfurization of exhaust gases coming from thermal power plants. Desulphurization technology removes the sulfur oxide (SOX) generated in burning fossil fuels by spraying limewater onto the exhaust gas so that the chemical reaction causes the SOX to be absorbed and removed. The absorbed SOX is recovered as gypsum for a secondary use.

Valves for flue gas desulfurization are deployed in lines for sending limewater in proportion to the amount of exhaust gas and recovering the gypsum, and each one can control on/off and the flow rate.

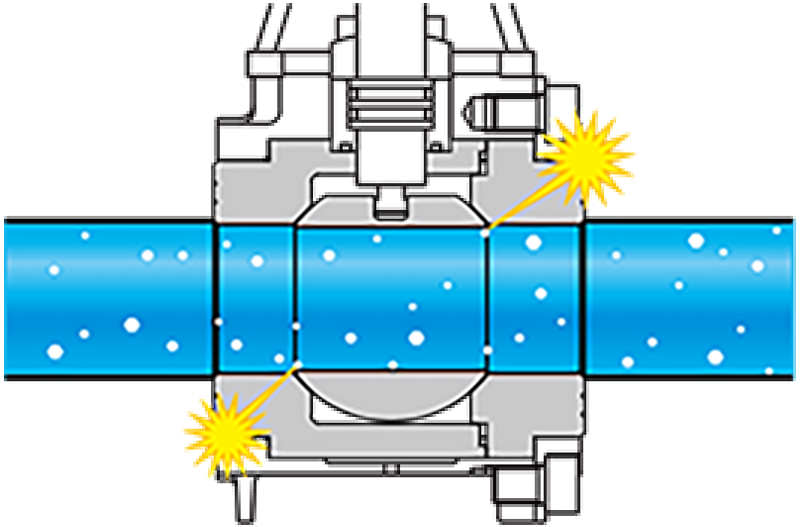

However, there was a problem that needed to be solved. Both limewater and gypsum are slurries – fluids mixed with solid matter – that cause abrasion and corrosion of metal valves. Therefore, a new material with better abrasion and corrosion resistance than metal was needed. At about that time, Fujikin began its relationship with the Kyoto Ceramics Company (now known as Kyocera), which produces fine ceramics.

Metal valves are weak against slurries (fluids with solid matter mixed in).

Metal valves are weak against slurries (fluids with solid matter mixed in).

Ceramic is baked clay and can be found in the "old ceramic" cups and dishes that we use in daily life. On the other hand, "fine ceramics" is a high-precision and high-performance ceramic made from refined powder that has its chemical composition tailored to its required use and is fired and molded through a controlled process.

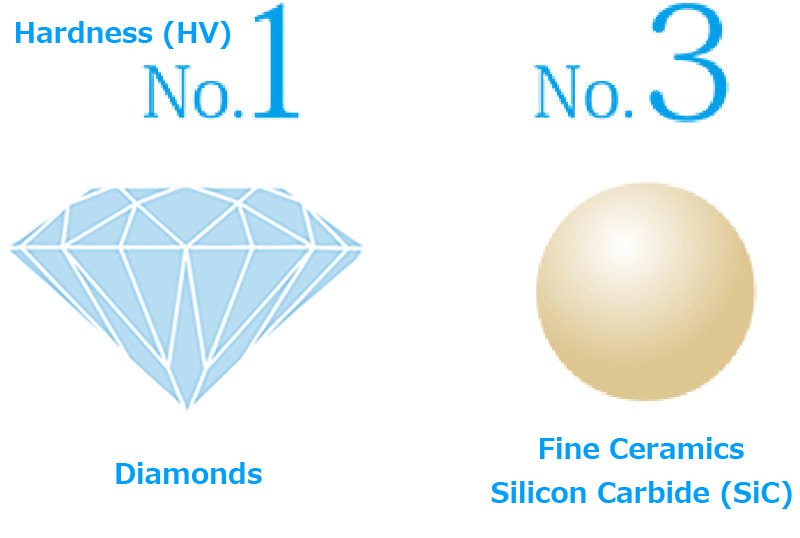

Its greatest characteristic is that it is hard. Against a typical material such as aluminum (Al203), stainless steel is 7.5 times harder, whereas silicon carbide (SiC) is 11.5 times harder, boasting the third highest hardness, close to the highest, which is diamond. It also has excellent abrasion, corrosion and heat resisting properties. Surely, these special characteristics are the most suitable for valves used in flue desulfurization facilities.

At the time, fine ceramic was commonly used as a material for integrated-circuit packaging but never for a device the size of a valve.

For this reason, in the initial development stages with Kyocera, breakage was common during the firing stage and it could not meet the requirements to stop the leaking of fluids.

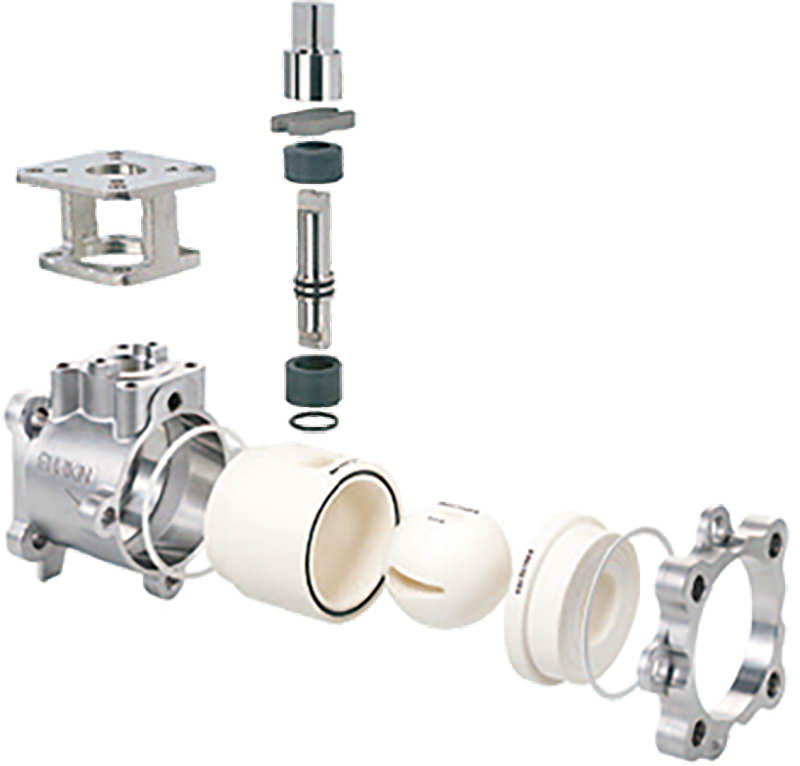

We overcame such problems step by step. First we developed a standard product for flue gas desulfurization that met the demands of society. However, following additional focus in mass production, in September 1981, we announced the practical implementation of the Phoenix™, the world's first fine ceramics valve. This news created a great sensation in the industrial world and it won numerous awards in Japan and America for being a revolutionary new product.

The evolution of the Phoenix™ and the COSMIX™.

The evolution of the Phoenix™ and the COSMIX™.

With an aim toward reducing the capacity and weight of the Phoenix™ by half while also drastically lowering the cost, Fujikin successfully developed the COSMIX™. As similar anti-pollution took hold outside Japan, Fujikin also expanded to overseas markets, becoming highly valued for contributing to environmental solutions in many countries.

Just as flue gas desulfurization facilities demand abrasion and corrosion resistance, paper and iron and steel plants need abrasion resistance, while chemical plants require corrosion resistance. Thus Fujikin's products play a role in many countries and industries around the world.

After developing valves of alumina fine ceramics, which boasts a high purity of 99.5% for standard products and 99.9% for specialized products, Fujikin now produces valves of such various materials as silicon carbide, silicon nitrade and zirconia. The possibilities for flow control equipment continue to expand.