Nanotechnology

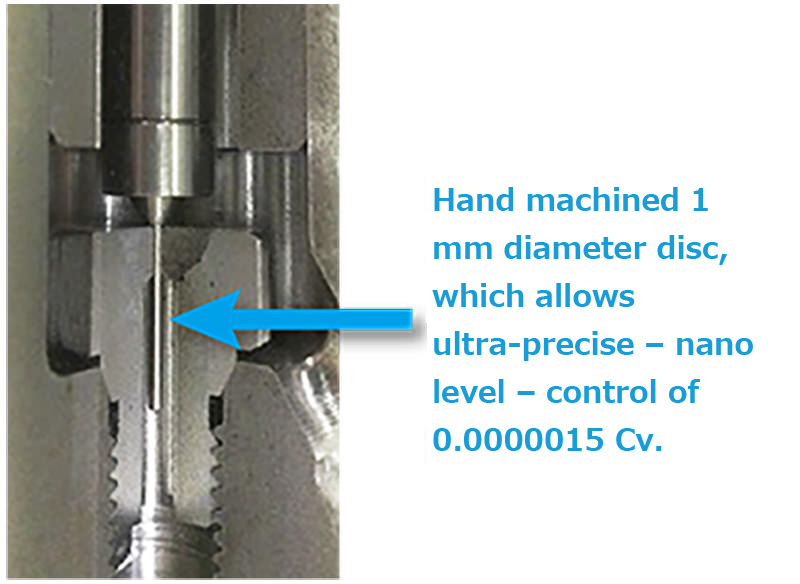

Defying the common techniques of hand machining, ultra-precise nano level control was born.

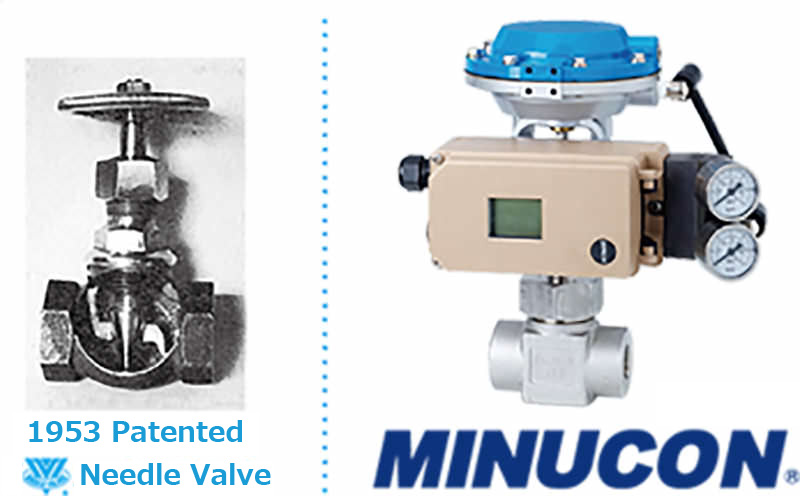

As a manufacturer of ultra-precision flow control systems with a focus on special valves, Fujikin took the first chance and developed the needle valve in 1953 to control the flow of delicate gases.

In an era when expensive imported products were still mainstream, Fujikin's needle valve was highly valued from all aspects and became our main product. Since then, Fujikin has made countless technological innovations, culminating in the MINUCON® pneumatic control valve.

The needle valve has a disc in the form of a long and narrow needle for precise control of gases and fluid flow.

To reach the limits of precision, the MINUCON® defies the common hand machining methods of big manufacturers and uses a technique to create a valve body with a diameter of 1 mm. This has made it possible to achieve an ultra-precise – nano level – control of 0.0000015 Cv.

Cv is the volume of water in US Gallons that will flow per minute through an open valve with a pressure of 1 psi. That small value of 0.0000015 Cv when the valve is open means that it is possible to have an accurate flow of 0.006 ml of water per minute.

How much is 0.006 ml? Although we do not know how many ml are in a sparrow's tear, human tears are between 0.02 ml and 0.05 ml. In other words, the MINUCON® can accurately and precisely contol the continuous flow of a large tear over 10 minutes.On the other hand, it is able to control a wealth of variations up to 5 Cv.

The MINUCON®, with its excellent control of microscopic flow rates, makes it is easy to notice a leak of colorless and odorless gas in gas mixing processes. A product that supports various Cv values, temperatures and pressure, it is being put into use in many fields.

Today, fuel cell vehicles rise in popularity, Fujikin's valves are used in compressors and dispensers of every hydrogen station. To work under such high pressure, an outstanding stainless steel forged body is used. As global awareness of environmental conservation rises, rapid expansion of the market is expected.

Furthermore, precise fluid control is required in superconductivity facilities, as well as equipment used to produce silicon wafers for semiconductors and for pharmaceutical tests. Throughout the past half century, Fujikin's needle valve has accumulated technology and will continue to lead the evolution and growth of the era.