Stick IGS

2012 9th

Cho Monodzukuri Grand Award for Parts: Machinery Award Awarded Product

The world's first successful modularization of a high purity gas supply system, this new product revolutionizes the gas supply system design process and succeeds conventional technology with a new design mechanism.

In the Cho Monodzukuri Grand Award for Parts organized by The Monodzukuri Nippon Conference and Nikkan Kogyo Shimbun, held on November 28th 2012, Fujikin's "Stick IGS" was awarded the Machinery Award. We have attained the ninth consecutive awards and updated the record of the awards number. We sincerely express our gratitude to everyone for their warm support.

1. Details and features of the product

(1)Background

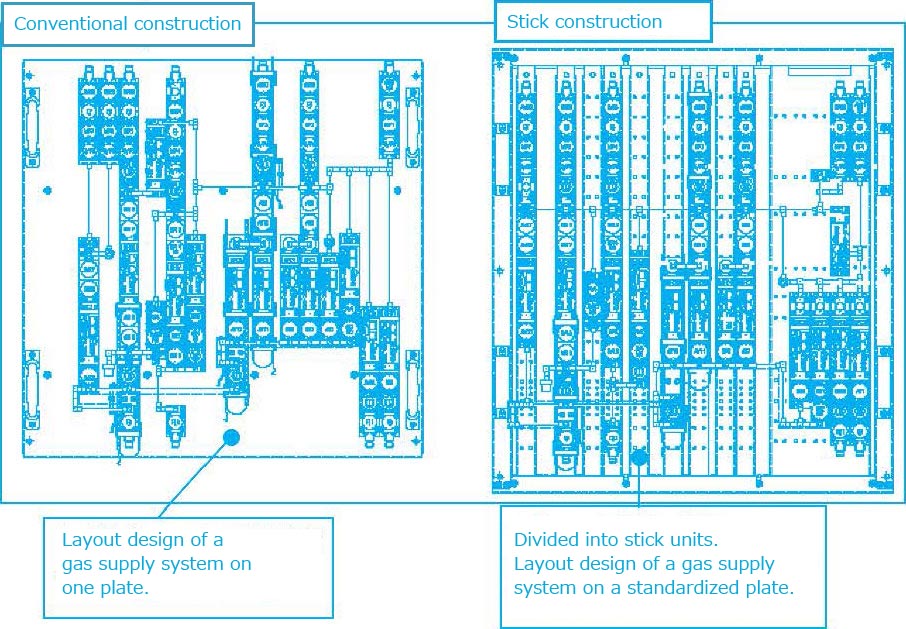

The structure of a gas supply system in a semiconductor manufacturing equipment. Because various designs are generated according to diversifying customer's requirements, gas pattern design of the gas supply system required cost of designing and manufacturing and a long manufacturing period.

To respond to the diverse requests of our customers, only in the base (plate) part which becomes the base, approximately 500 specimens were designed each time, production occurred each time, and it was an inefficient precision part.

We thoroughly analyzed approximately 1000 kinds of gas patterns, standardized the plate by the subdivided stick concept and decided to prepare six kinds of stick types. As a result, it was possible to cover 80% of the total gas pattern and to modularize and pattern the gas supply system. Simplifying makes it possible to standardize production, making it possible for overseas production of complicated gas supply systems that could only be produced in Japan, contributing to shortening the production period and cost reduction effect.

2. Evaluation items

2.1 Creativity of technology

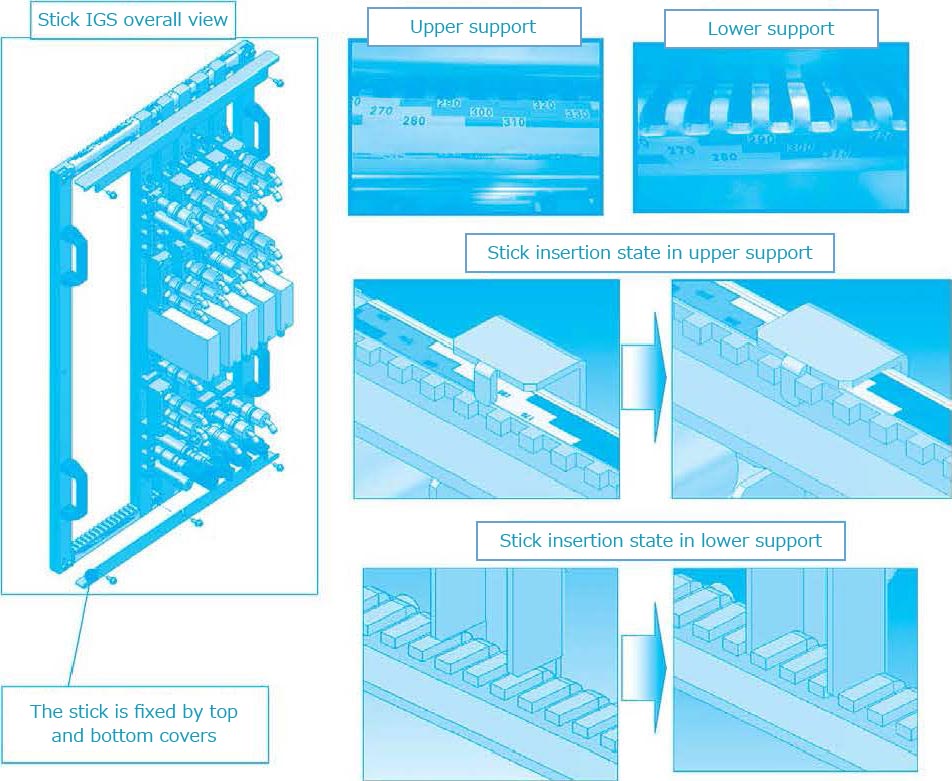

(1)To fix each stick, we adopted a concave-convex structure that takes hints from the wedge construction of wooden shrines made in ancient Japan, and vibration resistance is taken into consideration with no screws being used.

(2)We converted ancient Japan's design concept for traditional wooden architecture to metal.

(3)The structure is made up of 10 sticks hung with 1 upper and lower support.

(4)It is not just strong, by using the weight of the stick, it supports the structure.

(5)The upper and lower supports that support the heavy load of the sticks are stainless steel, and they are constructed with a thickness and rigidity that can support the required heavy load.

(6)The sticks and upper/lower supports are fixed in position together with a concave-convex structure that considers maintainability.

(7)The concave-convex part is precision manufactured with laser machining, and then bent for completion.

(8)Anticipating deformation after bending the stainless steel, it has been designed so that they will fit perfectly together after deformation.

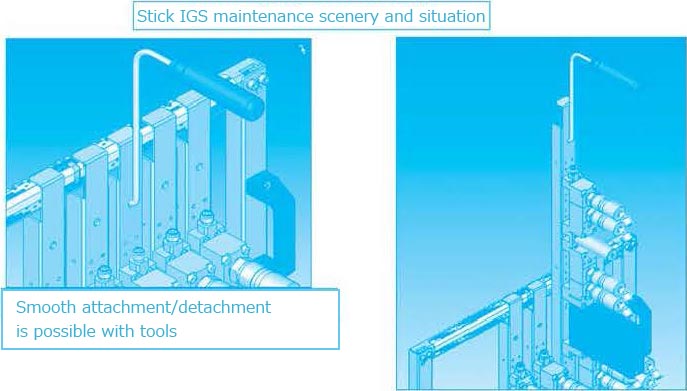

(9)It has a structure that allows simple installation and removal of stick units to support sudden change requests from customers, and can be constructed to freely change to every gas pattern.

(10)The recess is machined with a 10 mm pitch in order to support the various gas patterns.

(11)By combining the standardized sticks, the completed structure is able to support the various gas patterns.

(12)In order to prevent mistakes when installing the sticks, 3 different colored stickers are used to match the support with the stick width.

2.2 Performance

Together with the change from the conventional structure to the stick structure:

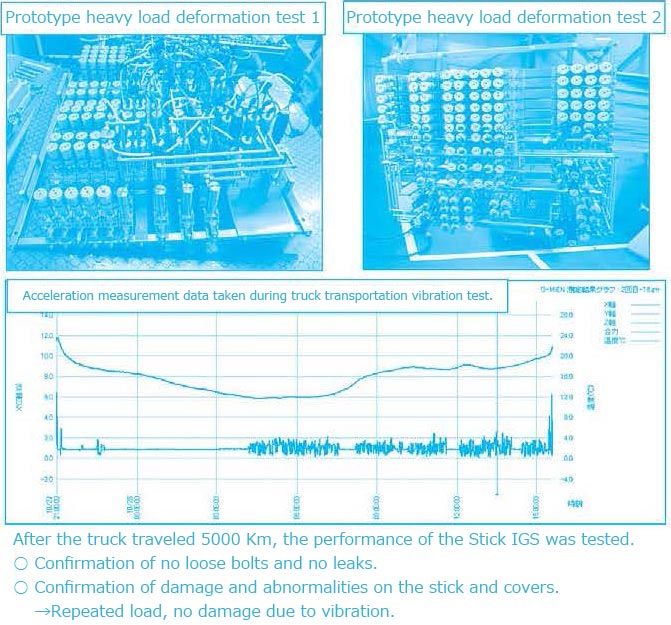

(1)We performed various tests such as stick load deformation tests, leak tests and vibration tests, etc., and confirmed that the performance is equal to or higher than the conventional structure.

(2)Rigidity and vibrations were particularly important, so we focused on reducing the flexibility when heavily loaded, and also pursued resistance against vibrations coming from transportation and equipment.

2.3 Economy

- (1)Energy saving construction

- Gas supply systems are installed in semiconductor manufacturing equipment such as etchers, CVD, etc., and use various types of gases depending on the characteristics of each equipment. Since gases that are liquified at room temperature are included, heating is applied to the relevant gas line in order not to liquefy. The stick has an ecological construction that reduces the amount of heat transfer to the plate by having a smaller area of heat dissipation. (30% reduction in power consumption compared to conventional construction)

- (2)Lead time

- By standardizing the stick plate, design and manufacturing for every change is avoided, and it is possible to reduce the lead time by 50%.

- (3)Overall optimization

- The newly developed Stick IGS contributes to cost reduction in manufacturing by using a standardized and optimized reusable design that enables modularization and patternization, which the conventional methods of construction do not have.

2.4 Product recruitment record and forecast future proliferation prospect

Since its sales launch in December 2011, a domestic semiconductor equipment manufacturer - A Company has adopted it as a gas supply system. Not only in Japan, but device manufacturers all over the world are also gradually adopting it as a gas supply system for semiconductor manufacturing equipment. (Current adoption as of November 2012: 140 equipments)

In the process from design to equipment selection to final inspection, the gas supply system, which was a product like a handmade product of each item, as well as the skills of the employees involved in the process, had problems in terms of delivery, and thus price.

By stick structuring the gas supply system,

(1)By making it possible to pattern the gas supply system with several kinds of modules, it leads to shortening of manufacturing process,

(2)Standardizing of production can be aimed, moreover, it becomes possible to produce overseas, and a large reduction in costs can be expected.

(3)As a result, it is expected to become a widely adopted gas supply system.

2.5 Safety and environmental considerations

- (1)Safety

- It is easy to handle because it is designed so that the maximum weight of one stick is about 5 kg or less.

- (2)Environmental considerations

- For all parts materials etc. that make up the Stick IGS, we have investigated hazardous substance surveys and meet the standards.

3. Others

Posted newspaper article

In the 2012.5.24 Nikkan Kougo Shimbun (morning publication), it was published in the article "Fujikin gas supply modularization with support for 80% of semiconductor manufacturing."

4. Related patents

- 1 application (Reference number: P110142 patent application 2011-113531)