AR2000 equipped with two-way communication function

The valve's role is to quickly and reliably stop and precisely control the flow (pressure and flow rate) of gas and liquid. Also, valve problems may stop the flow of manufacturing, so a function is necessary to detect and predict the occurrence of failures beforehand.

Together with the evolution of technology, rapid high capacity internet environments are quickly being popularized, and the era of IoT (Internet of Things) is beginning with everything around us being connected to the internet, and not just computers and mobile phones.

Fujikin's electronic valves have also evolved to keep pace with the internet, and "Smart valve" equipped with measurement function with various sensors made full-scale correspondence to IoT possible. One such advanced product is the electronic valve "AR2000-LEAF" (tentative name).

We adopted a stepping motor for the AR 2000. The AR2000 uses a stepping motor and realized high operation performance such as high speed response, precise control and high resolution (2000:1) which was difficult with conventional electric motor valves. Together with quickly executing instructions coming from the host system such as a computer, various sensors check if the pressure and flow rate is being maintained as designated, if there are external leaks and if there are any possibilities of failure occurring, and then immediately feeds back to the host system.

Fujikin's technology combines valves and sensors together to control the operation to match the constantly changing state, and prevents the possibility of problems before they happen. This approach opens the way for the IoT era as an advanced parts manufacturer, and we were featured in JETRO's (Japanese External Trade Organization) international business information program "The World is Now - JETRO Global Eye."

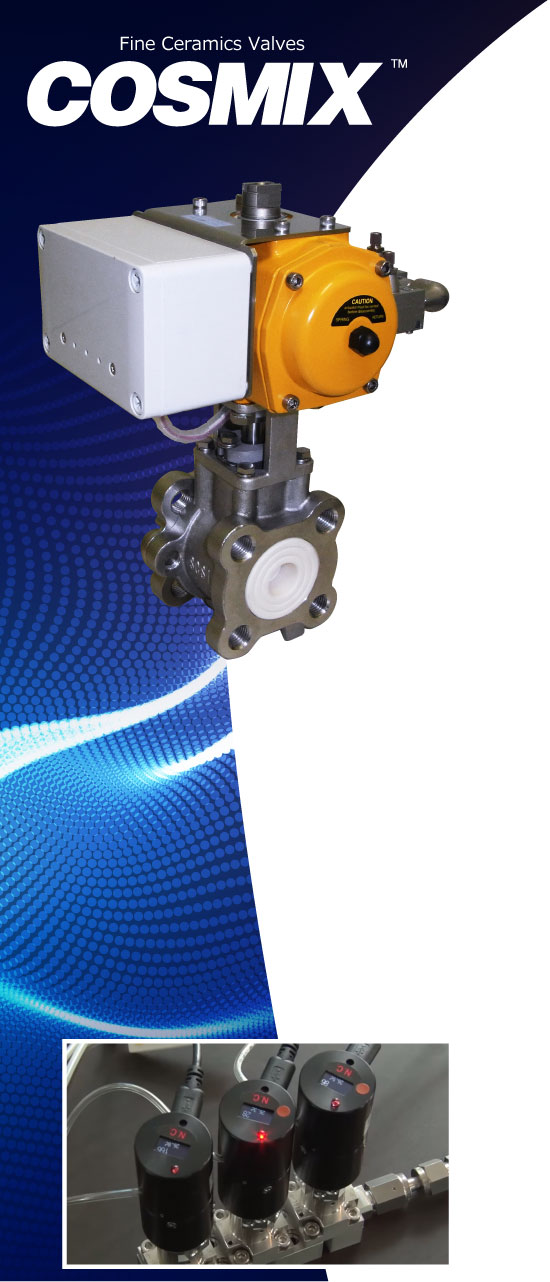

Cosmix™ monitors and diagnoses the valve opening and closing drive torque

The fine ceramics valves "Cosmix™" equipped with "valve opening and closing drive torque monitor and diagnosis system" is expected to be at the core of smart factories alongside the AR2000. Maintenance for fine ceramics valves is extremely important, because they are used in severe conditions such as flue gas desulfurization plant for thermal power stations. Up to now, periodic inspections and maintenance have been carried out based on the experience of veteran engineers, but due to the lack of engineers and difficulty of skill transfer, it became necessary to have valve systems that can do self-diagnosis from the standpoint of preventative maintenance.

Accordingly, we developed a system that monitors the valve opening and closing drive torque with sensors and does a diagnosis on maintenance necessity, and then sends the data to a tablet or smartphone with Wi-Fi communication. As a result, it has become possible to realize a more efficient and stable operation of the plant.

Furthermore, in collaboration with ConnecTec Japan, Fujikin is developing various sensors to detect pressure, temperature, humidity and gas, and also promoting the development of support with industry wireless standards and retrofit types for existing valves. In the future we will not stop at IoT, we also have the outlook of developing systems that diagnose and use the large amounts of data collected by the sensors with AI (Artificial Intelligence).